Solar thermal energy, a tool for ecological transition in the agri-food industry

October 4, 2019

With its stringent health requirements and energy-intensive processes, the food industry remains one of France's biggest emitters of greenhouse gases. As the food industry embarks on its ecological turnaround, sustainable sourcing of raw materials, eco-design of products and optimization of logistics go hand in hand with more rational use of energy and recourse to renewable energies. Solar heat production therefore represents one of the key solutions for the industry's ecological transition, by directly substituting its consumption of fossil fuels.

Agri-food processes adapted to solar thermal energy

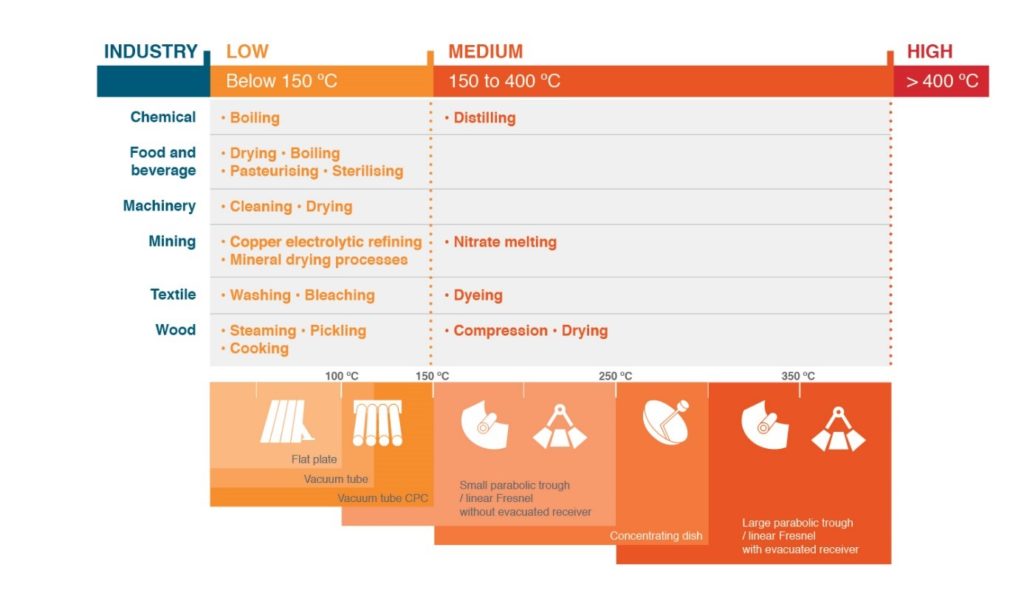

Thanks to large-scale solar thermal power plants, the food industry has a technological tool capable of covering a significant proportion of its heat consumption, over a wide range of processes and temperatures.

Most food manufacturing processes operate at low (<150°C) and medium (150 - 250°C) temperatures.

Low-temperature operations in food processes

The most significant energy consumption comes from the preparation of raw materials and their transformation into finished food products. Both heat transfer fluids are often used: hot water (100°C).

A multitude of applications of this type include: temperature maintenance for mixing ingredients, drying, evaporation, fermentation, cooking, etc.

Sanitary applications include pasteurization, sterilization, production line washing and CIP.

Solar thermal technologies such as flat-plate collectors and evacuated tubes are particularly efficient and competitive for these low-temperature applications (<150°C), especially in European countries where solar radiation is moderate and often diffuse.

Solar thermal energy is also effective for preheating fluids such as steam, air or others, for example, for heating boiler make-up water when the process requires direct injection of steam into the food product.

Solar thermal energy can also be used to preheat condensate returning from the process to the steam boiler.

Other medium-temperature applications in the food industry

Heat consumption in the medium temperature range (150-400°C) requires heat transfer fluids such as steam, air or thermal oils.

Among the most common food processing applications in this temperature range are roasting, baking operations on foods such as bread products, refining of complex food products such as sugar, and so on.

These applications generally require the use of concentrated solar thermal technologies, which are best installed in geographical areas with high direct sunlight, for productivity reasons.

Over most of France, this second type of heat consumption is therefore more difficult to satisfy with solar thermal technologies.

Breakdown of industrial heat consumption and associated solar thermal technologies

@SolarPayback

Renewable, storable heat to complement the existing system

To compensate for the intermittent nature of solar radiation, the heat produced by solar thermal technologies can be stored at low cost in the form of hot water (<100°C), for use at night or later (daily). In Denmark, some solar heating networks even benefit from high-capacity inter-seasonal storage facilities.

Concentrated solar thermal power plants can also store the heat they produce in the form of molten salts (300°C-600°C), as is the case with some facilities in the Middle East.

Whether using flat-plate collectors or concentrating solar power technologies, a solar thermal system connected to an industrial site is not intended to cover the site's entire heating needs. It is always integrated into an existing system (usually a gas or biomass boiler), which guarantees total security of supply when solar production is insufficient.

Sunti offers manufacturers and local authorities an investment-free solution for the supply of solar heat and self-consumption photovoltaic electricity, helping them to achieve their environmental objectives while generating significant and immediate savings on their energy bills.